|

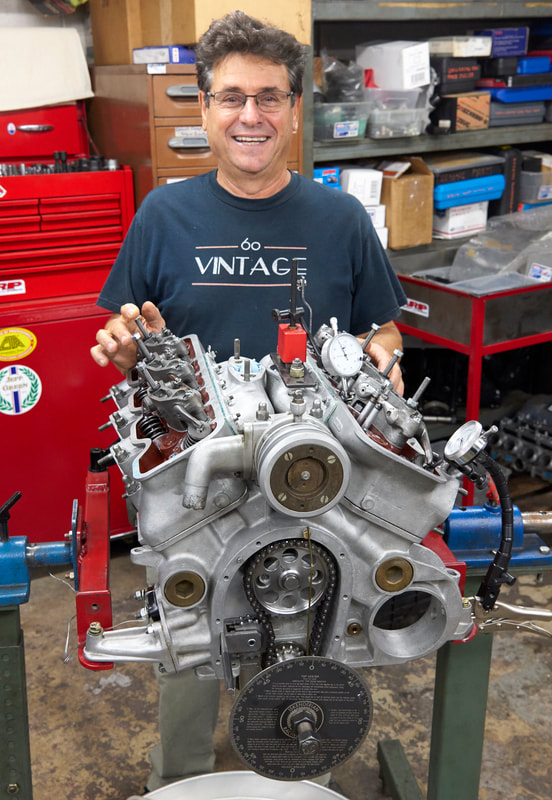

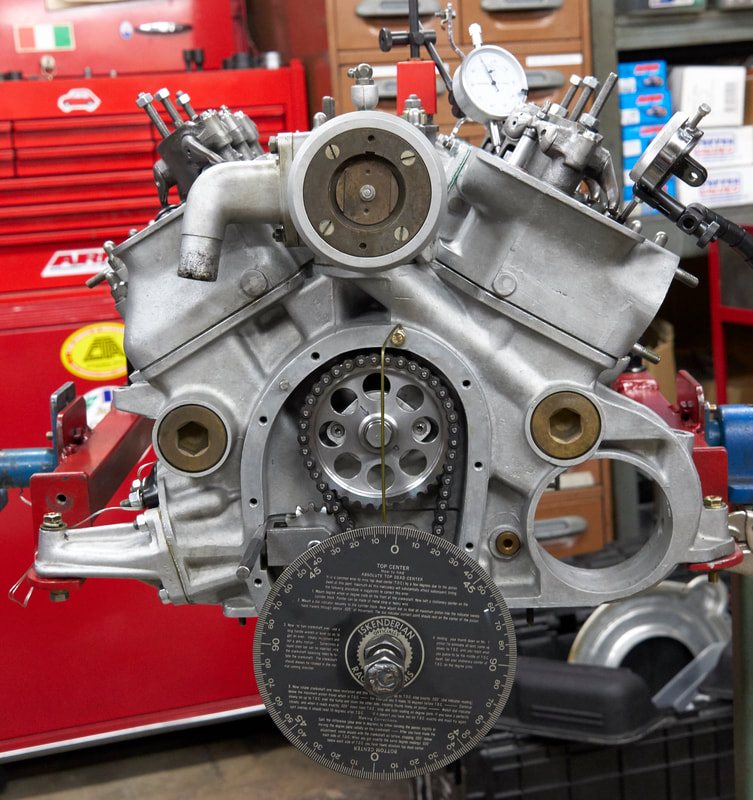

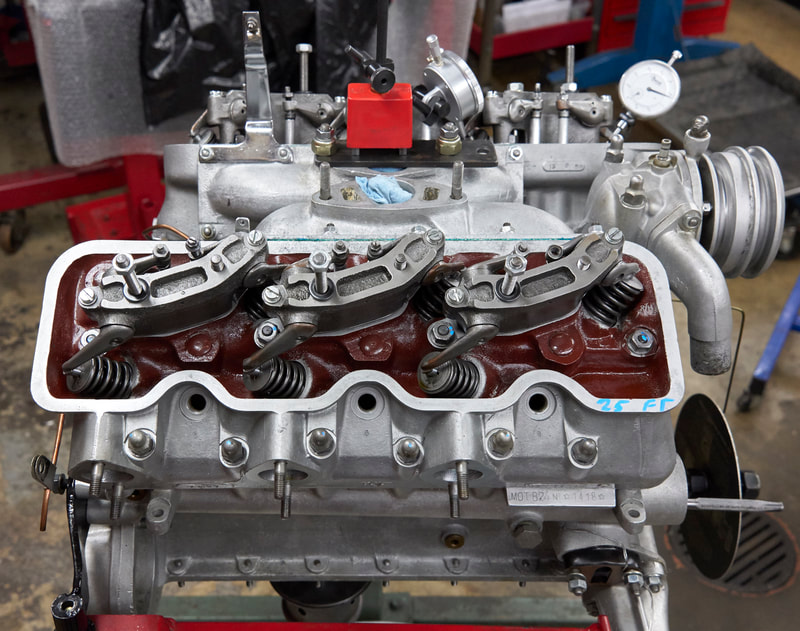

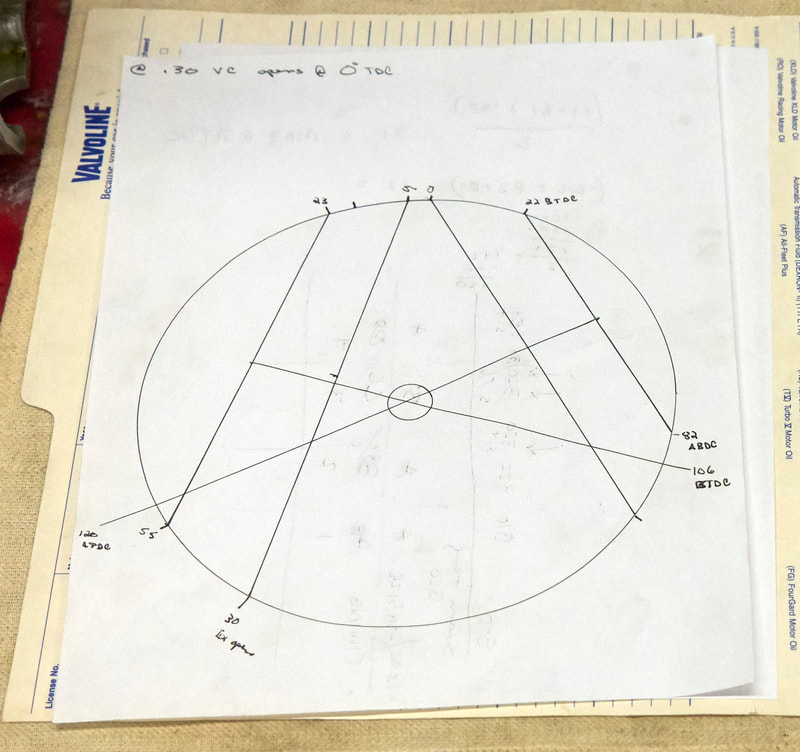

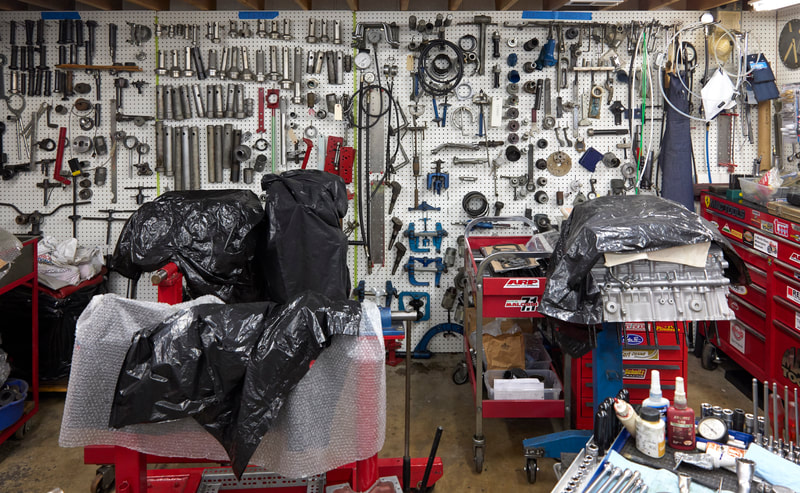

Timing the cam on the Aurelia can be a bit challenging. The factory method, as outlined in their data sheets and found in the Aurelia manual, sets the timing from the point of opening and closing on the lobe (typically no. 1 intake) and places the cam a certain distance from TDC on the crankshaft. This is not an uncommon approach and was used by other manufacturers of the time, but its not one recommended here. The problem is that many cams have been either remade and reground, or made anew, and its not clear that the beginning point of action on the lobe is at exactly the same point as on the factory original. And a little variation means a lot. Another way is outlined by Martin Cliffe of Omicron, and can be found in the Aurelia workshop manual (see Paul Mayo for your copy). This method is used more commonly today. Cliffe's excellent writeup outlines all timing issues on the Aurelia, with the first part relevant here. He outlines how to set the timing from point of maximum lift of the lobe - the "Maximum Opening Point" (MOP). Imagine a symmetrical lobe, with its central axis as the point of MOP. That then is located against the TDC by a given degree distance. Giovanni D'Avola, was rebuilding an Aurelia engine at Autosprint, his shop in Chicago. He has worked on Lancias, Ferraris and all Italian cars for years. He source a new cam from Cavalitto, and to set it up right, the following process was used: 1) find TDC. Done with a degree wheel and measuring the top of the cylinder. Degree wheel zeroed for TDC. 2) find central axis on lobe by measuring from both sides of the lobe, that is, bracket the central axis. 3) keep chain taut using a chuck in the tensioner. Also rotate in one way (clockwise) so the chain doesn't back off as this can distort the readings significantly. 4) locate lobe centers for both intake and exhaust for one cylinder. 5) place Intake MOP after TDC per formula (see Martin Cliffe article for figuring). For this cam, Intake MOP was 120 degrees ATDC but only for this s.5/6 cam, it is different for other cams). If cam timing is unknown, the cam can be placed by determining a middle between Intake and Exhaust MOP, and placing this middle at a known event (such as TDC of the compression stroke) when both are equally closed. Check with your own cam folks before doing. 6) the results were checked by mapping the opening and closing points for intake and exhaust valves, and comparing these with the factory settings noted from the beginning. Its not so important the opening/closing points be exactly the same (as these points vary depending on clearances used), but rather that lines drawn on the degree wheel between opening and closing moments (both for the factory settings and as observed) are parallel. See drawing below (done by Charlie at Autosprint) for both intake and exhaust - all very good. In the end, its all buttoned up as the engine is close to running. and here are some of the cars at Autosprint:

1 Comment

|

CategoriesArchives

July 2023

|