Lancia Aurelia

camshafts

General

The camshaft lies in the deep interior of the engine. A long but precisely machined piece of steel, its lobes activate remote valves, mechanically telling the valves when to open and close with great precision. Some call them the “ heart of the engine” as their design establishes the performance characteristics of an engine as critically as any other single part. By setting the timing for the valve operation, they control when and how quickly valves open and close, and the incoming and exhausting of the combustion gases.

Lancia engines are typically oriented to maximize driver pleasure. Their engines were designed to provide good low end torque (for ease of driving) as well as reasonable performance through the rev range of the engine. Small differences in cam design make for big differences in engine performance. Details matter a great deal.

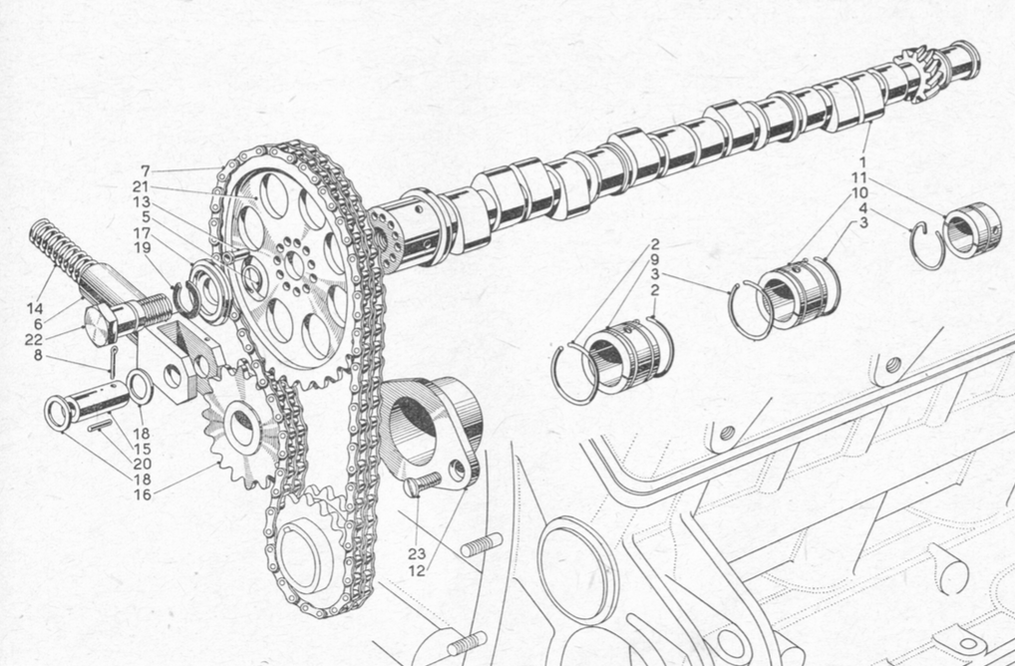

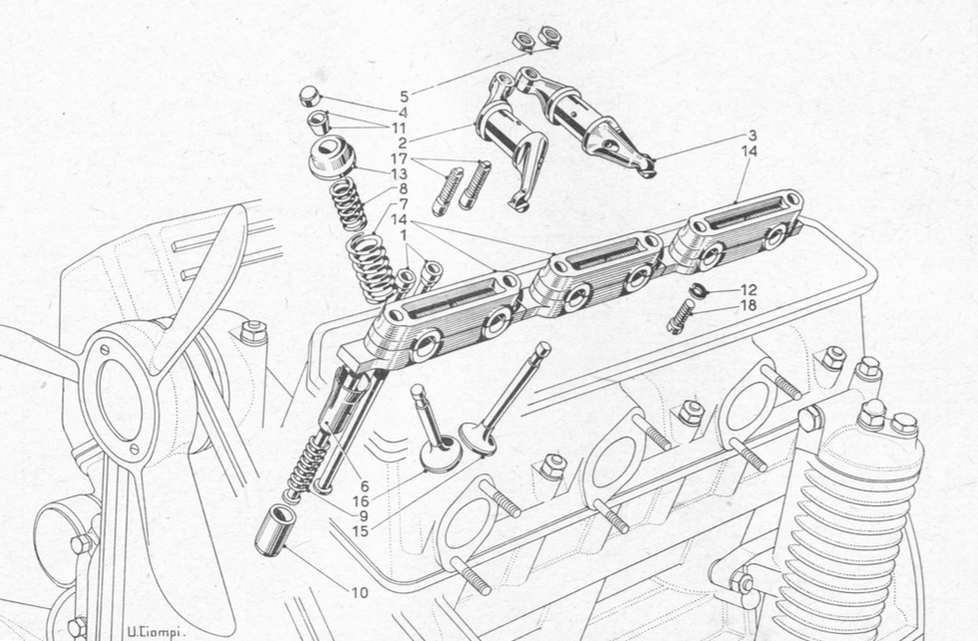

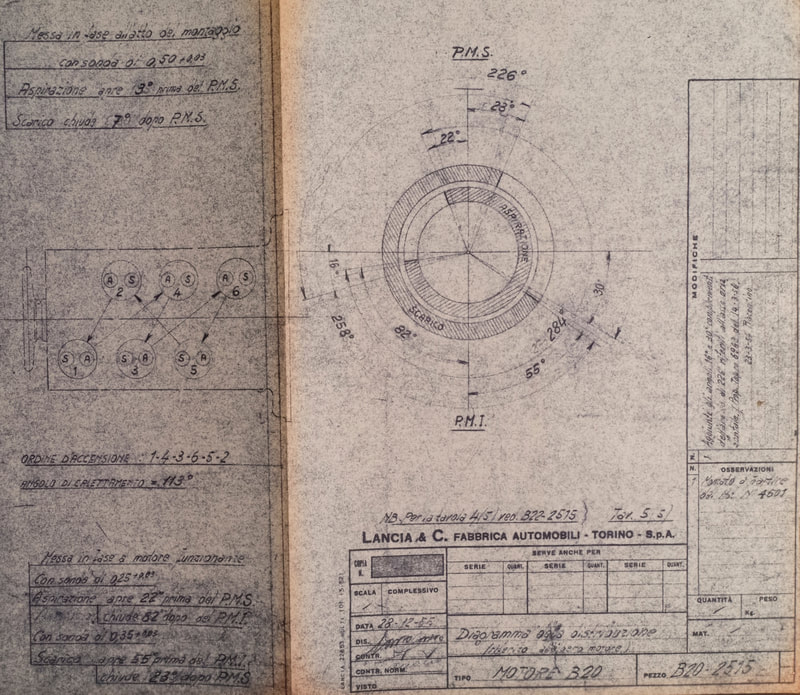

The Aurelia V6 has one central camshaft, located in the center of the engine, above the crankshaft. The lobes on the camshaft are ridden by pushrods, tucked into hardened lifters, and activate the valves up above through rockers. Lancia used offset rockers so that the valves could be placed where they want them, but other than that, the basic arrangement is not uncommon. Lancia engines had very well designed cams, for good driving characteristics. Much of this was due to the fact that Lancia designed their cams for each version of the Aurelia understanding how the car would be used; the cam was one part of an integrated design, along with valve sizing, compression ratios, and gear ratios for each version - all were planned and matched to work together.

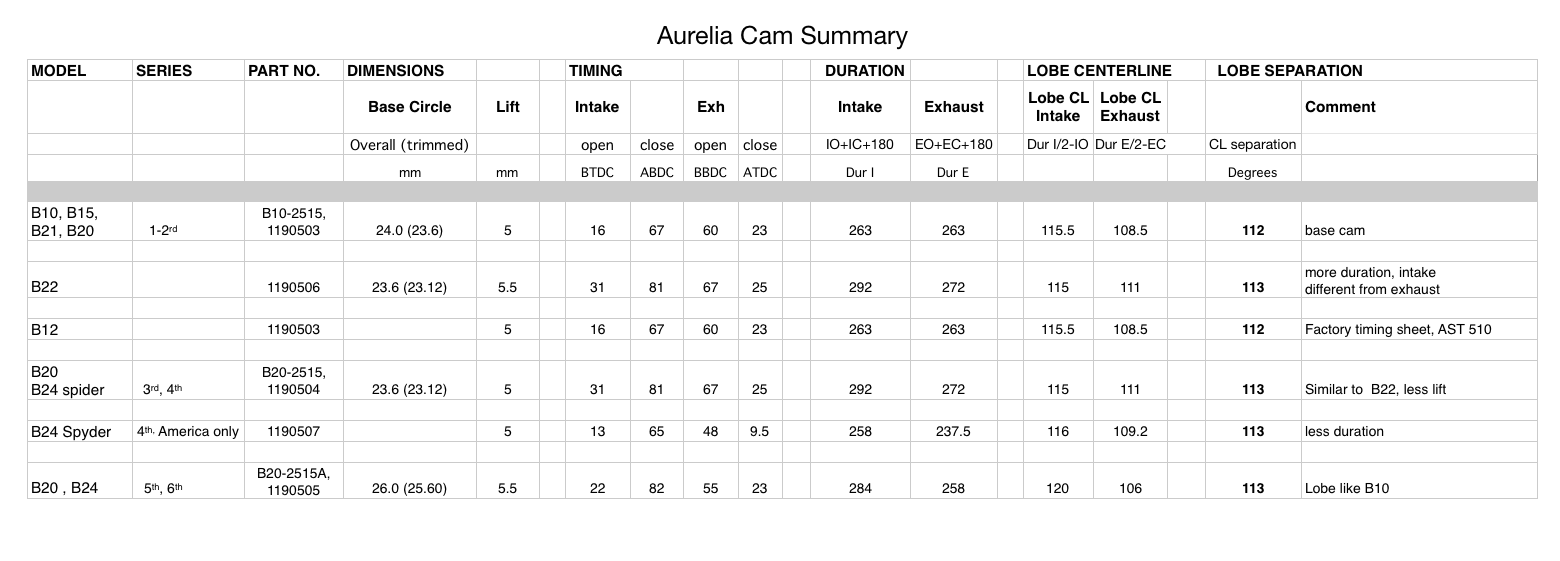

Lancia used several different cams in the Aurelia, and specifically tailored them to each version of the model. Yet they never published a technical summary of the different cams used, so it has long been difficult to determine the differences between the cams. This then is an effort to lay down what cams were used in the Aurelia - it is based on material from the Lancia archives and De Virgilio's own papers. A large number of cam drawings were reviewed and camshafts tested.

Key issues in camshaft design are the lift (the height of the cam lobe), the lobe profile and the duration. Less studied, but quite important in comparing cam performance is the lobe center separation - that is, the separation between the intake lobe and the exhaust lobe at their top (or centerlines). In addition, one way to distinguish Lancia cams is to consider their base circle, that is, the minimum diameter of the cam lobe.

Different versions

How many camshafts did Lancia make for the Aurelia, and how did they differ? Factory documentation reveals that Lancia made five different camshafts for the Aurelia production cars, as follows:

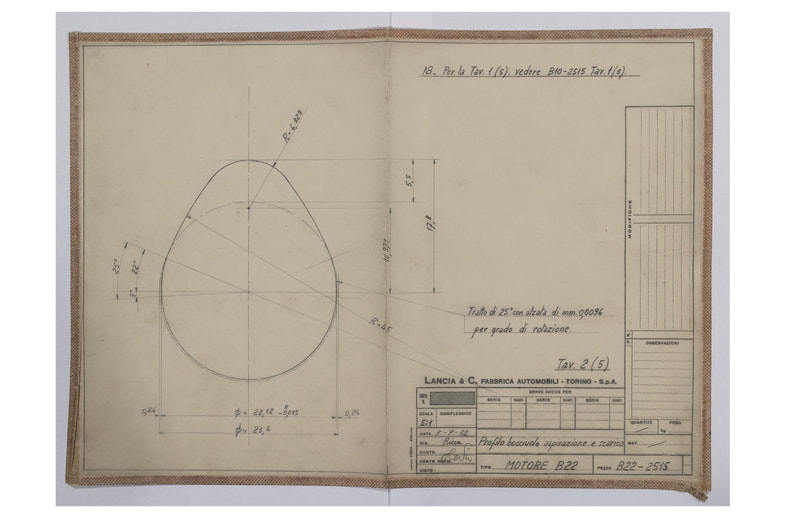

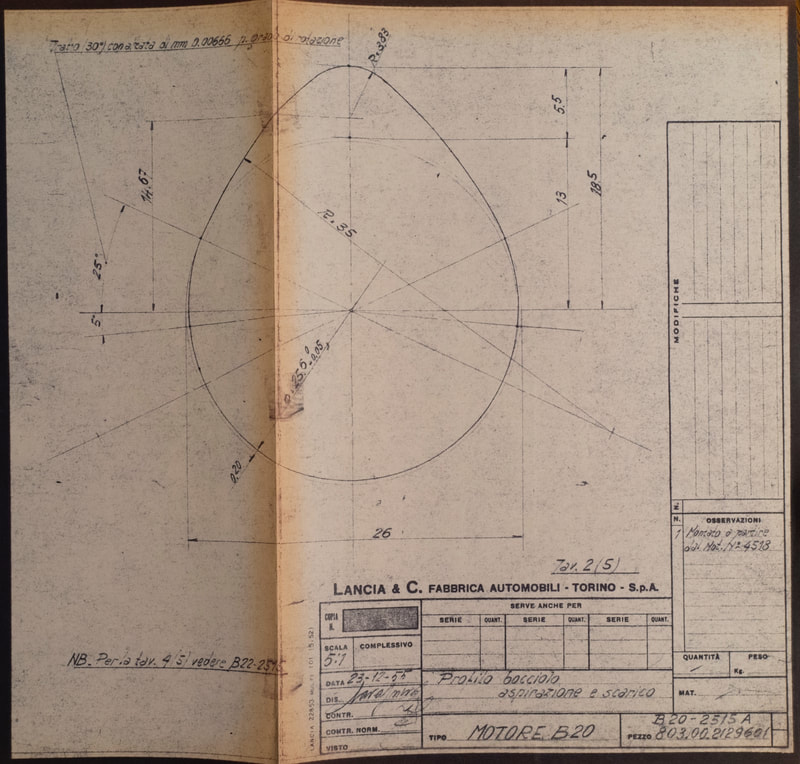

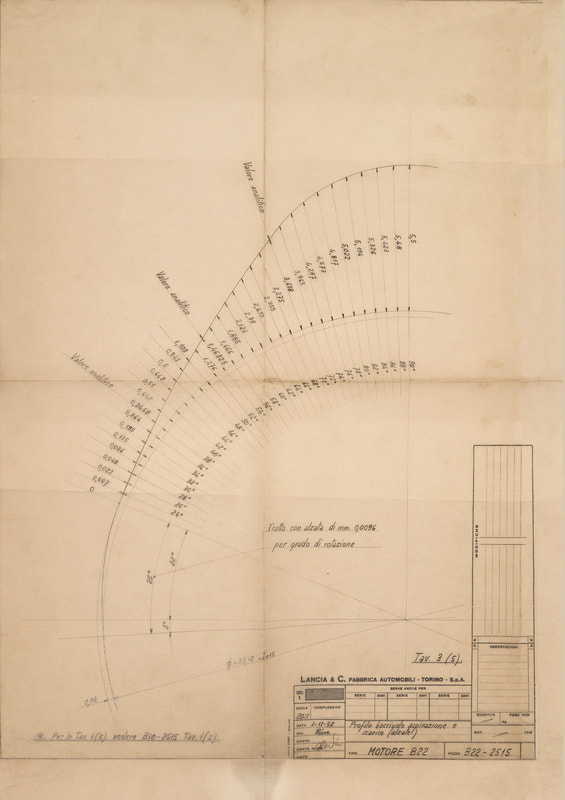

Tri-arc design

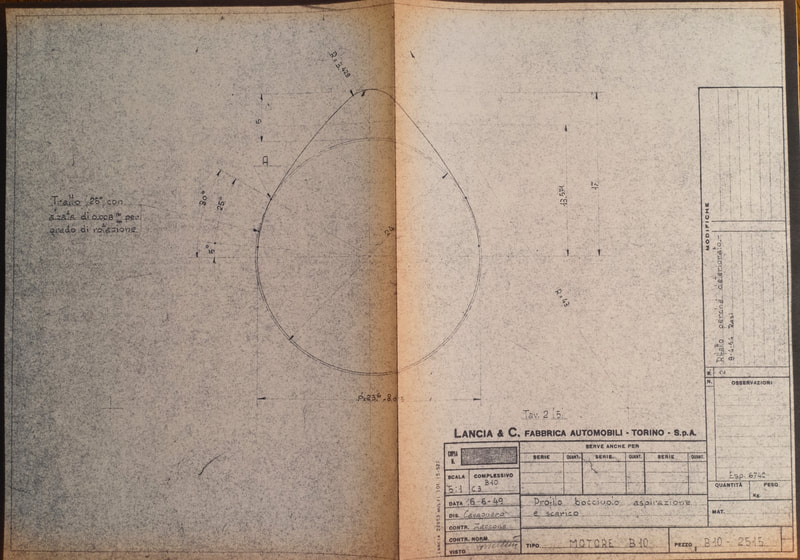

What was the design of the lobes for the Aurelia cam? In general, they are designed with a set of three curves, a tri-arc concept, making up the lobe profile. The three different arcs are the base circle (radius in the center), the general transition to the ramp, and the curve at the top of the lobe. The location of the radii points are changes, giving different profiles or adjusting to different lifts. This approach works well in simpler times, and is easy to draw and manufacture vantages point. Current cam design is more sophisticated, and focuses on the transition period for valve opening, using more sophisticated designs to extract more power.

Findings

In general, there are several things that are common to Aurelia cams. They basically came in two base circles, although there was a small variation in the original smaller size - 24mm was the original, 23.6mm for the B22 and B20, and then 26mm for the B20 s.5/6 cars. Lift was typically either 5 or 5.5mm, translating to 7.5mm or 8.75mm lift at the valves (the rockers were 1.5:1 ratio). Timing and duration changed a few times, although all the sedans had the same timing, as did the B22 and sB20 s.¾ cars. Finally, all cams were designed with similar lobe center separation, 113 degrees (one was 112 degrees).

When one reviews all the cams together, the intriguing and impressive part of the story is that all these different cams are one package, an assembly of modifications, a few changes made effectively to balance between continuity and customization. Its a dance, and De Virgilio, as the designer leading the effort, did it well with very good results.

Aftermarket cams

The most famous aftermarket cams for Aurelia were made by Nardi. Located nearby Lancia, they made several different cams, but details are not easy to come by, and actual first hand experience with original Nardi cams is rare. In 1980, one was documented and had 6.5mm lift and a very different exhaust lobe location. This would have given rough low end running - and I saw a B20 with reportedly an original Nardi cam and it ran just like that. Rough idle, clearing around 3000rpm and revving freely after that. Recently, Jean-Marie Levallois mapped a brand new B22 Nardi cam with a 24.4mm base circle (different from any of the stock cams), still with 6.5mm lift.

American experience of special Aurelia cams comes largely from Megacycle, a cam making company in California. They accumulated a lot of Aurelia experience, much due to west coast Lancista, such as Steve Katzman, Steve Snyder and Dick Buckingham sharing cams they found. Megacycle developed four different Aurelia cams, with their most common number 90199 , very good with low end torque and top end breathing to about 5500rpm. It is not clear if they are still making cams.

Remade cams from Italy come in many varieties. Cavalitto used three different suppliers, and there are likely others. Sergio Allais will make whatever you want, with hundreds of different lobe profiles on a rack, and you tell them the desired timing. Many Italian aftermarket cams are based on the stock s.4 cam sometimes with a bit more heat, either by increased lift (say to 6.5mm, done by reducing the base circle), or with different timing in a new cam, with less lobe CL separation, say of 108 degrees. There are even more aggressive cams made for competition. Bosato, an older Lancia tuner, was said to have made a special cam quite nice, too, but never seen it. And just for the exotic, some years ago Rosani had a factory prototype cam from 1953, with different lobe profiles for intake and exhaust, never put into production.

(A note on base circles: these dimensions were shown on drawings and used for design and manufacture. A measured cam will reflect a slight bit of trim, about .4mm less diameter.)

The camshaft lies in the deep interior of the engine. A long but precisely machined piece of steel, its lobes activate remote valves, mechanically telling the valves when to open and close with great precision. Some call them the “ heart of the engine” as their design establishes the performance characteristics of an engine as critically as any other single part. By setting the timing for the valve operation, they control when and how quickly valves open and close, and the incoming and exhausting of the combustion gases.

Lancia engines are typically oriented to maximize driver pleasure. Their engines were designed to provide good low end torque (for ease of driving) as well as reasonable performance through the rev range of the engine. Small differences in cam design make for big differences in engine performance. Details matter a great deal.

The Aurelia V6 has one central camshaft, located in the center of the engine, above the crankshaft. The lobes on the camshaft are ridden by pushrods, tucked into hardened lifters, and activate the valves up above through rockers. Lancia used offset rockers so that the valves could be placed where they want them, but other than that, the basic arrangement is not uncommon. Lancia engines had very well designed cams, for good driving characteristics. Much of this was due to the fact that Lancia designed their cams for each version of the Aurelia understanding how the car would be used; the cam was one part of an integrated design, along with valve sizing, compression ratios, and gear ratios for each version - all were planned and matched to work together.

Lancia used several different cams in the Aurelia, and specifically tailored them to each version of the model. Yet they never published a technical summary of the different cams used, so it has long been difficult to determine the differences between the cams. This then is an effort to lay down what cams were used in the Aurelia - it is based on material from the Lancia archives and De Virgilio's own papers. A large number of cam drawings were reviewed and camshafts tested.

Key issues in camshaft design are the lift (the height of the cam lobe), the lobe profile and the duration. Less studied, but quite important in comparing cam performance is the lobe center separation - that is, the separation between the intake lobe and the exhaust lobe at their top (or centerlines). In addition, one way to distinguish Lancia cams is to consider their base circle, that is, the minimum diameter of the cam lobe.

Different versions

How many camshafts did Lancia make for the Aurelia, and how did they differ? Factory documentation reveals that Lancia made five different camshafts for the Aurelia production cars, as follows:

- B10 - this car used was the first Aurelia cam, designed in 1949. It anchored the Aurelia lineup and was used in both 1.8 liter and 2.0 liter motors for the B10, B15, B21, B20 s.1 and s.2. Its base circle was 24mm and the lobe had 5mm lift.

- B22 - developed in the end of 1952, it had a slightly smaller base circle of 23.6mm, its lift was increased to 5.5mm, with a different lobe profile and revised timing, making it the most aggressive Aurelia cam.

- B20 - for s.3 and s.4 B20s, also B24 s.4, it was a combination of the B10 and B22 cam designs. From the B22 it took its base circle and timing. WIth 5mm lift like the B10, its lobe profile was slightly revised from the B22, being even more pointed.

- B20 - for s.5 and s.6, (also B24 Convertibles s.5 and s.6), it had a significantly larger base circle of 26mm, in order to reduce valve train wear. Its lobe profile was the same as the earlier B10, but enlarged with 5.5mm lift. Timing was also changed.

- B24 Spider America - a small number of B24 Spiders were made with a detuned cam, with the lobe profile and lift of the B10, and uniquely revised timing having the least duration of any Aurelia. It was used only on the few B24 Spiders with motors marked "A" for America, while the other B24 Spiders used the cam similar to B20 s.3 and s.4 .

Tri-arc design

What was the design of the lobes for the Aurelia cam? In general, they are designed with a set of three curves, a tri-arc concept, making up the lobe profile. The three different arcs are the base circle (radius in the center), the general transition to the ramp, and the curve at the top of the lobe. The location of the radii points are changes, giving different profiles or adjusting to different lifts. This approach works well in simpler times, and is easy to draw and manufacture vantages point. Current cam design is more sophisticated, and focuses on the transition period for valve opening, using more sophisticated designs to extract more power.

Findings

In general, there are several things that are common to Aurelia cams. They basically came in two base circles, although there was a small variation in the original smaller size - 24mm was the original, 23.6mm for the B22 and B20, and then 26mm for the B20 s.5/6 cars. Lift was typically either 5 or 5.5mm, translating to 7.5mm or 8.75mm lift at the valves (the rockers were 1.5:1 ratio). Timing and duration changed a few times, although all the sedans had the same timing, as did the B22 and sB20 s.¾ cars. Finally, all cams were designed with similar lobe center separation, 113 degrees (one was 112 degrees).

When one reviews all the cams together, the intriguing and impressive part of the story is that all these different cams are one package, an assembly of modifications, a few changes made effectively to balance between continuity and customization. Its a dance, and De Virgilio, as the designer leading the effort, did it well with very good results.

Aftermarket cams

The most famous aftermarket cams for Aurelia were made by Nardi. Located nearby Lancia, they made several different cams, but details are not easy to come by, and actual first hand experience with original Nardi cams is rare. In 1980, one was documented and had 6.5mm lift and a very different exhaust lobe location. This would have given rough low end running - and I saw a B20 with reportedly an original Nardi cam and it ran just like that. Rough idle, clearing around 3000rpm and revving freely after that. Recently, Jean-Marie Levallois mapped a brand new B22 Nardi cam with a 24.4mm base circle (different from any of the stock cams), still with 6.5mm lift.

American experience of special Aurelia cams comes largely from Megacycle, a cam making company in California. They accumulated a lot of Aurelia experience, much due to west coast Lancista, such as Steve Katzman, Steve Snyder and Dick Buckingham sharing cams they found. Megacycle developed four different Aurelia cams, with their most common number 90199 , very good with low end torque and top end breathing to about 5500rpm. It is not clear if they are still making cams.

Remade cams from Italy come in many varieties. Cavalitto used three different suppliers, and there are likely others. Sergio Allais will make whatever you want, with hundreds of different lobe profiles on a rack, and you tell them the desired timing. Many Italian aftermarket cams are based on the stock s.4 cam sometimes with a bit more heat, either by increased lift (say to 6.5mm, done by reducing the base circle), or with different timing in a new cam, with less lobe CL separation, say of 108 degrees. There are even more aggressive cams made for competition. Bosato, an older Lancia tuner, was said to have made a special cam quite nice, too, but never seen it. And just for the exotic, some years ago Rosani had a factory prototype cam from 1953, with different lobe profiles for intake and exhaust, never put into production.

(A note on base circles: these dimensions were shown on drawings and used for design and manufacture. A measured cam will reflect a slight bit of trim, about .4mm less diameter.)

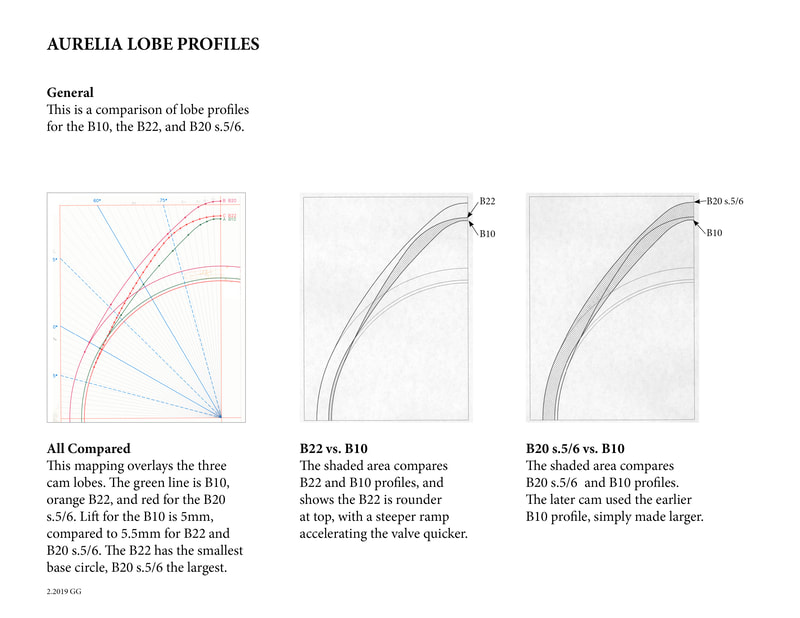

Here are the original factory design drawings for B10, B22 and B20 s.5/6 cam lobes, with a visual comparison. At the time this was done, lobe information for the B20 s.3/4 wasn't available. Its been found since - its profile is basically the B22 adjusted for 5mm lift.

The pdfs below include:

1) the chart of the stock Aurelia cams

2) a comparison of the lobe profiles for the B10, B22 and B20 s.5/6.

3) an older listing of many different cams, including aftermarket ones

1) the chart of the stock Aurelia cams

2) a comparison of the lobe profiles for the B10, B22 and B20 s.5/6.

3) an older listing of many different cams, including aftermarket ones

| cam_chart_redone_1.2019.pdf | |

| File Size: | 47 kb |

| File Type: | |

| cam_comparison_2019_.pdf | |

| File Size: | 545 kb |

| File Type: | |

| cam_summary_chart_1.09.pdf | |

| File Size: | 31 kb |

| File Type: | |

site design and content copyright G. Goldberg, images as noted Proudly powered by Weebly