Lancia Aurelia

Drawings

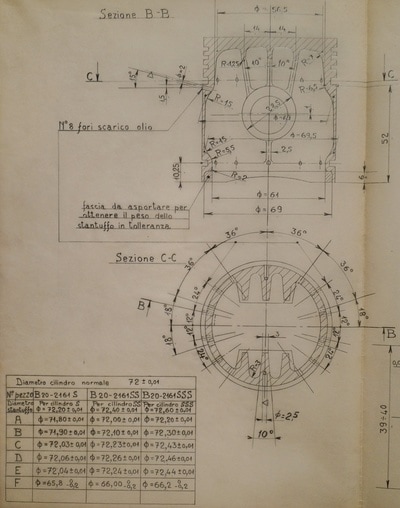

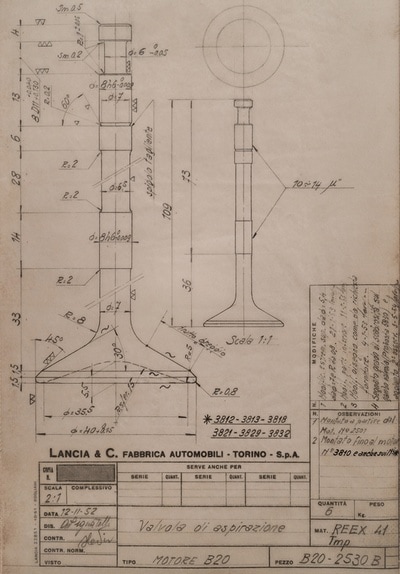

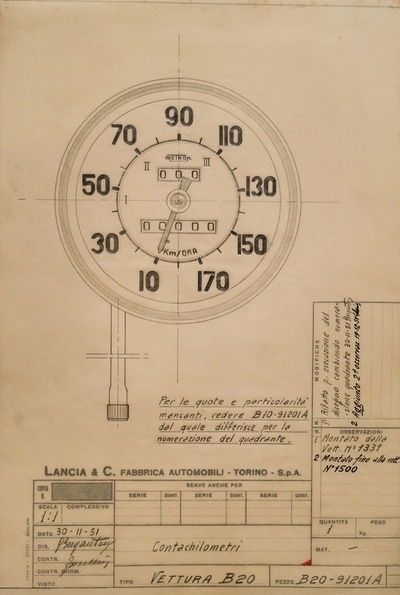

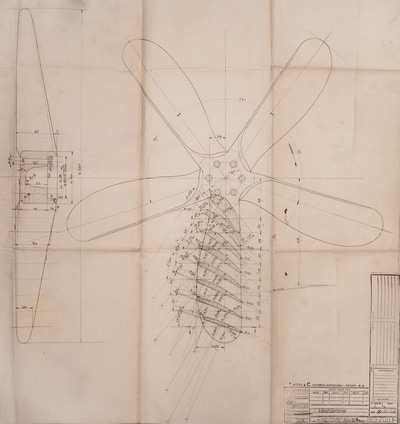

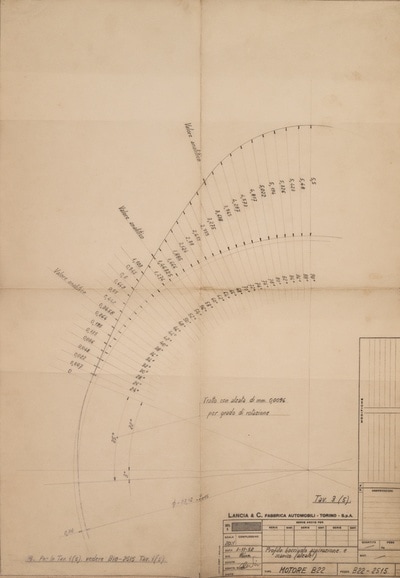

One of the reasons Lancias work so well is that they were fully designed products. They were the result of a very meticulous and thorough drawing process - where each piece, assembly and condition was studied in drawing. This may seem obvious to those not so familiar with the design process, but there are different levels of study one can use to make a product. Some are resolved on the working floor, a combination of skill and some "off-the-cuff" decision-making. Others, in particular large industrial concerns, resolve the problems and design the parts carefully in drawings, test in models and prototypes, before committing to production.

Where Lancia was special is that they used the standards of large scale operations (such as Fiat) to make relatively small numbers of cars. In addition, with production largely in-house, they were able to make changes rapidly, and cast or machine what they needed. The result was a very broad product range with extremely high levels of control and refinement.

This way of working was exciting for designers and engineers as they were able to solve problems to the highest quality levels and yet see the results of their work made closely. As a result, Lancia attracted very high quality designers and engineers, and was able to keep them.

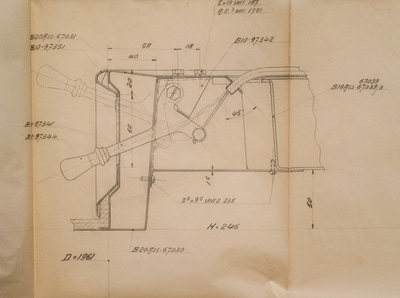

What stands out when looking at the drawings is the level of craftsmanship and skill in the details. A few are produced below. Some of the more spectacular ones simply are not reproducible on the web.

Where Lancia was special is that they used the standards of large scale operations (such as Fiat) to make relatively small numbers of cars. In addition, with production largely in-house, they were able to make changes rapidly, and cast or machine what they needed. The result was a very broad product range with extremely high levels of control and refinement.

This way of working was exciting for designers and engineers as they were able to solve problems to the highest quality levels and yet see the results of their work made closely. As a result, Lancia attracted very high quality designers and engineers, and was able to keep them.

What stands out when looking at the drawings is the level of craftsmanship and skill in the details. A few are produced below. Some of the more spectacular ones simply are not reproducible on the web.

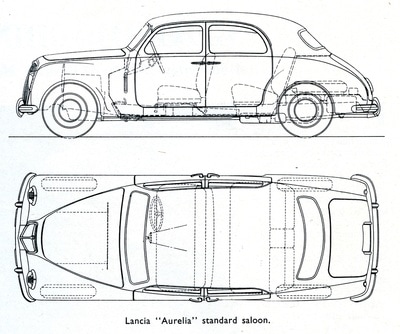

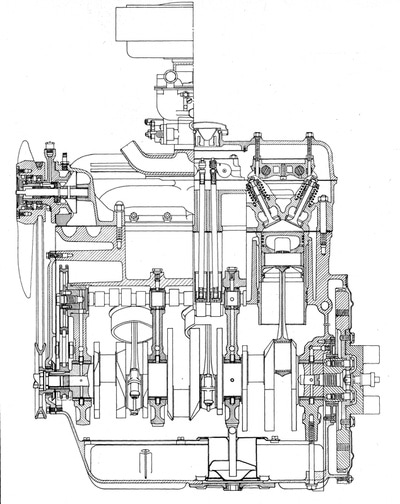

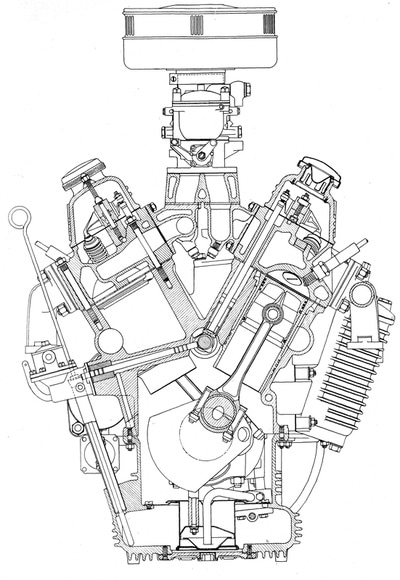

Engine and body drawings from Automobile Engineer, 1951:

Parts drawings

site design and content copyright G. Goldberg, images as noted Proudly powered by Weebly