|

In 2016 - the B20 had a problem. The front suspension wasn't quite right. It had been rebuilt some years back, but the parts weren't available to do it right, and the suspension would "clunk" badly on one side with dips or holes. It made driving frustrating, as one had to steer around road conditions, and then brace for the inevitable which would only happen when least expected. On smooth roads it wasn't a problem. But I live in a city, and the roads are lousy.

The options were limited: the knowledge base on the suspensions is limited to a few people - and while the local mechanic (Gianni at Autosprint in Chicago) was fully capable - as there is little he can't do - what he didn't have was any knowledge of what parts might be available. It would be a first time effort, and the car would be laid up while the communication went back and forth to Italy. Who knows if all the right parts and pieces would come together? The suspension, while not too difficult, has bits and pieces. One thought was to send it to Italy - but there would be little communication possible about what to do - they tend to do what they think is right, and it would be shipped back. A fair amount of risk there. In the end, conversations with Simon Thornley and Wayne Kelham were quite useful. They were fully committed to doing a full rebuild, and had just completed two s.2 B20 front suspensions in the past year. The sliding pillar has some slight variations over its lifespan on the Aurelia, and so their experience with the s.2 was useful. So too, they had been in good communication with Italy, about what new parts were available. So Gianni and I pulled the front axle out of the car in my garage, put the car up on stands, and the axle on a pallet. After about 20 pages (and endless phone calls) the axle was shipped to Thornley Kelham. They undertook a full rebuild, doing a crack test on the hubs, and finding one of the steering arms needing replacement. They went deep into the suspension, found the corroded tabs (not functioning very well, source of problem), plus a number of very worn out parts. They got new ones from Italy, cleaned it all up, and put it back together, rebuilding the brakes at the same time. And just to be sure, they put the axle on Simon's own B20 for a road test. The axle came back about 2 months after I shipped it to them, and was fitted right to the car. And the transformation was total - the ride in the front is not only supple, but controlled. Its a level of finesse that is just lovely. I had thought the standard for a good front end was our Appia with 60k original miles, but this was even better. Its been now two years since the work was done, and all is good! Many thanks to Simon, Wayne, and the team at their shop. Job well done!

0 Comments

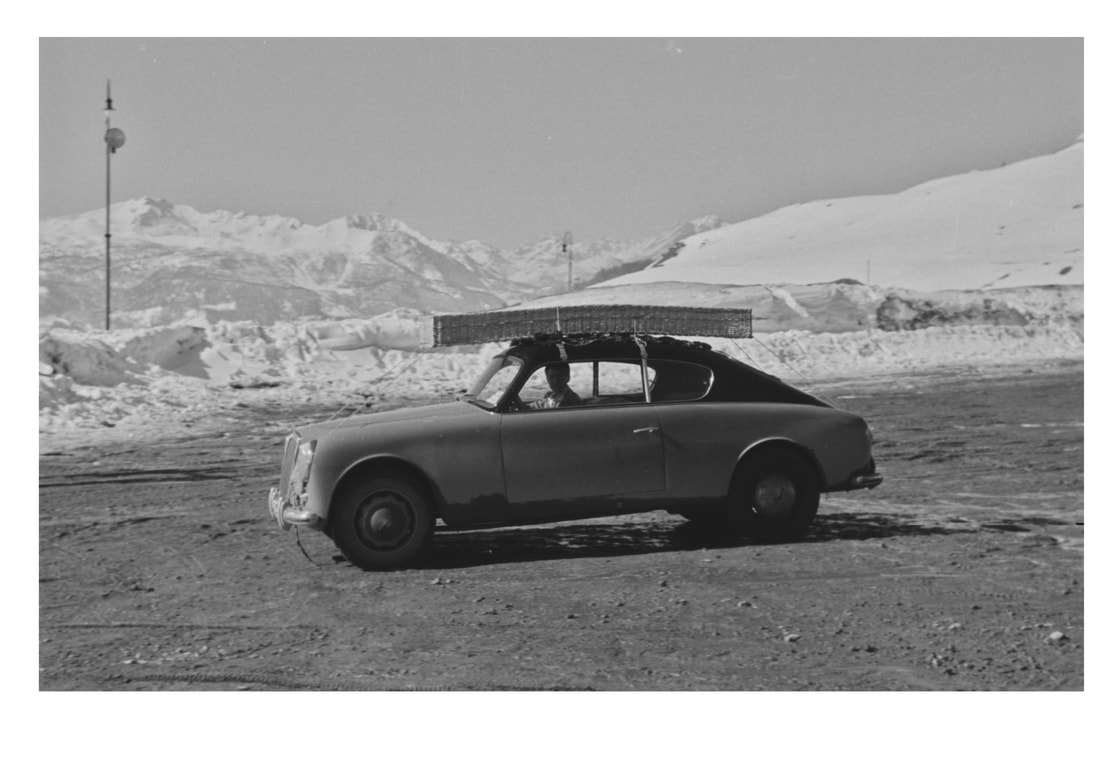

A short video of the rally in 1953 in the Italian Alps. Notable is the scenery, the quality of the landscape, a number of Aurelias (and some Alfas too...) and a shot of Gianni waiting at the top. Great character, sent by Massimo Fila. Toward the end is some great footage of an Aurelia berlina bouncing along some rough roads.Other rally cars include a Porsche, several Alfa Romeos and Fiats, the roads and cities in 1950s Italy,. Thanks to Centro Storico Fiat. Heading up to Wisconsin for the vintage car weekend, I was worried with a loud ticking from the engine. The local mechanic (Gianni) pulled the valve cover and checked the valve clearances - which should be done on a cold engine. This one was hot, so it not quite proper, but we found two loose rocker arms, and were able to get them back to the specifications shown by the other valves. (On an average, seems the valve lash was about .05mm tighter than when cold, but that is just a guess).

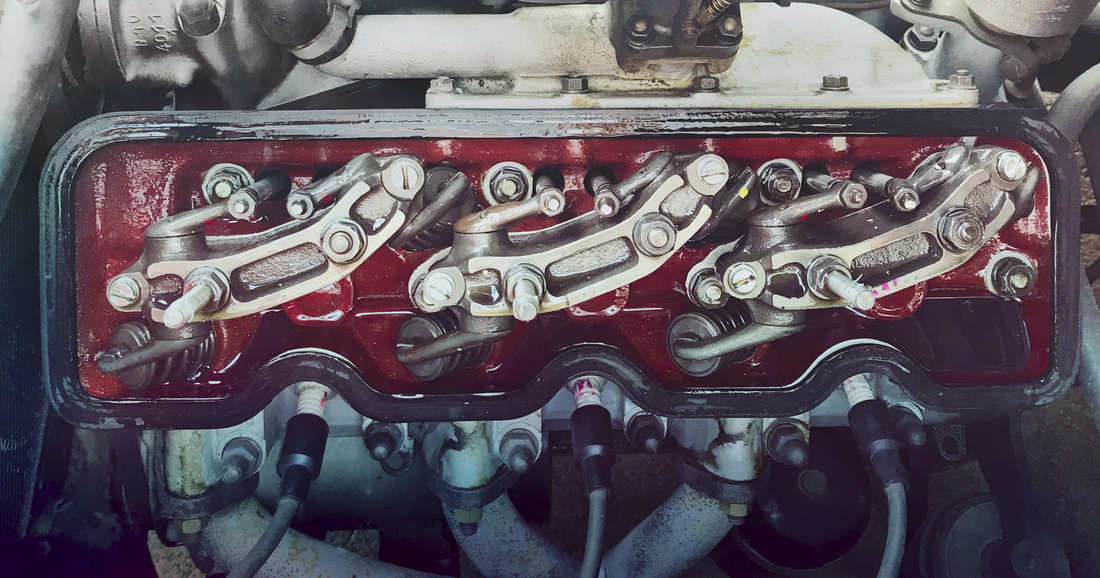

Here is a shot of the rocker arms and the pillow boxes that hold them. You can see the pushrods up top in pairs, coming from the cam in the valley of the "V". Then the clever rocker arms, in pillow boxes that are angled, so that the intake valve is rotated about 45 degrees closer to the intake, and the exhaust valves are on the bottom, close to the exhaust manifold. This way of rotating the valves was De Virgilio's clever improvement, first implemented in 1952 on the second series B20, and then used for all subsequent B20 and B24 engines. This car has the two single Webers as standard (the one for this bank is visible) and a special tubular exhaust. Massimo Fila Robbatino sent two interesting items: first is a marked up early Aurelia brochure. Both weights (in kg) and costs (in lira and dollars) are noted for the different models. Good fun. Max also sent in a video of his B20 running around the Peloponnese in Greece. The B20 was running well and being used as a modern car. And the roads - without traffic - looked great.....Thanks!

|

CategoriesArchives

July 2023

|

||||||||